Main features:

High grinding efficiency

High accuracy of the ground workpiece and good surface quality

Easy dressing with diamond roller dressing

Semi-finish and finish grinding processes for double or single endface grinding

Parallelism < 0.003 mm, flatness < 0.003 mm, Ra < 0.05 μm

High accuracy of the machined workpiece, direct error of 1-2μm for single disc parts

Product application range:

High-speed and high-efficiency grinding of peach-shaped surfaces of automobile engine camshafts

High efficiency grinding of crankshaft connecting rod journals, main shaft journals, flange journals, thrust faces and end faces for automotive engines.

It is mainly used for seals (silicon carbide, alumina ceramics, zirconia ceramics, metal ceramics, etc.), tools (carbide, PCD, CBN, HSS, etc.), ceramic valves, various powder metallurgy products and carbide products, etc.

Applicable grinding materials:

Cast iron category: chilled cast iron, ductile iron, grey cast iron, etc.

Steel parts: 20Cr, GCr15, CF53, 45 steel, 80B high elasticity steel, etc.

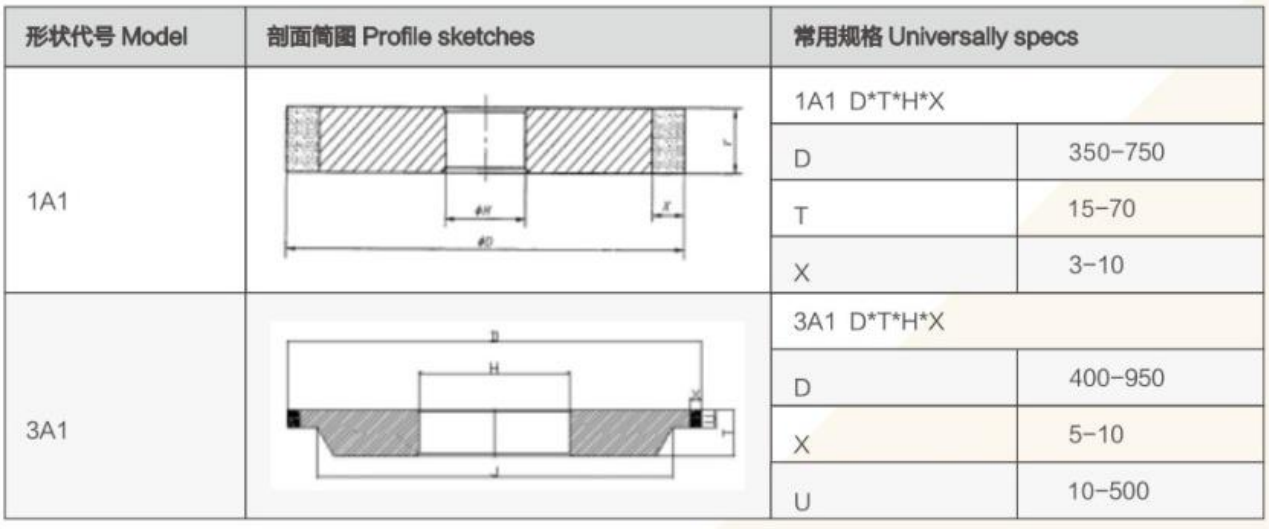

Shape code and sketch: