Automotive

WSS | CBN ball cage milling cutters in the automotive industry

For a long time, our country for car production and car maintenance of constant velocity universal joint mainly rely on imports, each year need to spend a lot of foreign exchange. After more than ten years, with the rapid development of China's automobile industry manufacturing technology, the professional technical team in the continuous improvement of manufacturing technology, research and development of automobile isochronous universal joint main parts blank precision forging technology and production technology.

「Introduction to the cage」

Chinese name:球籠

Foreign name: cage

Type:Important parts in the transmission system of a car

Industry:Automotive

Also known as:isometric universal joint

Part composition: bell-shaped shell, trigonal bearing or steel ball

Main checks: internal and external spline and thread size

WSS has witnessed significant developments in the automotive industry and is following the trends in the industry with significant advances in CBN ball cage milling cutters and is committed to providing our customers with more cost effective products!

The following are examples of successful WSS CBN ball cage milling cutters:

Use of tools

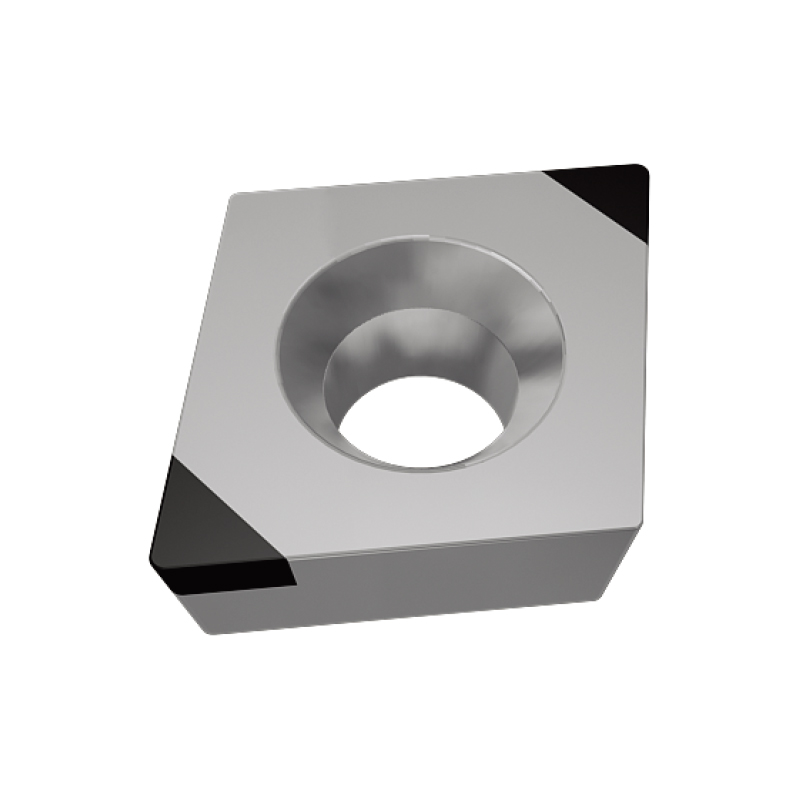

WSS CBN ball cage milling cutters have a simple structure, small size and light weight, and are strong and less prone to chipping, resulting in a more consistent life than conventional milling cutters, ensuring the quality of the machined surface while increasing machining efficiency.

Workpiece name: Ball cage

Workpiece material: hardened steel

Material hardness: HRC58°

Roughness : Ra1.6

Machining method: Milling

Processing parameters

Vc: 130m/min

f : 0.2mm/rev

Ap: 0.3 mm

T/L (lifetime): 2000 pieces

Machining workpieces

With WSS CBN ball cage milling cutters, milling instead of grinding is cost effective and ideal for many manufacturers in the automotive industry!

WSS is committed to providing the best tooling solutions. Manufactured from imported quality raw materials and relying on a team of experts and competent personnel, WSS aims for premium and consistent production quality, optimal tool life and targeted solutions for the automotive industry.

Examples of automotive parts processing of hardened steel materials

Examples of automotive parts processing of hardened steel materials

Powder metallurgy solutions for soft materials

Powder metallurgy solutions for soft materials

CBN tool solutions for machining carburised steel materials

CBN tool solutions for machining carburised steel materials

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining