There are three types of tool materials used for machining powder metallurgical parts: Cemented carbide tools, ceramic tools and cubic boron nitride tools.

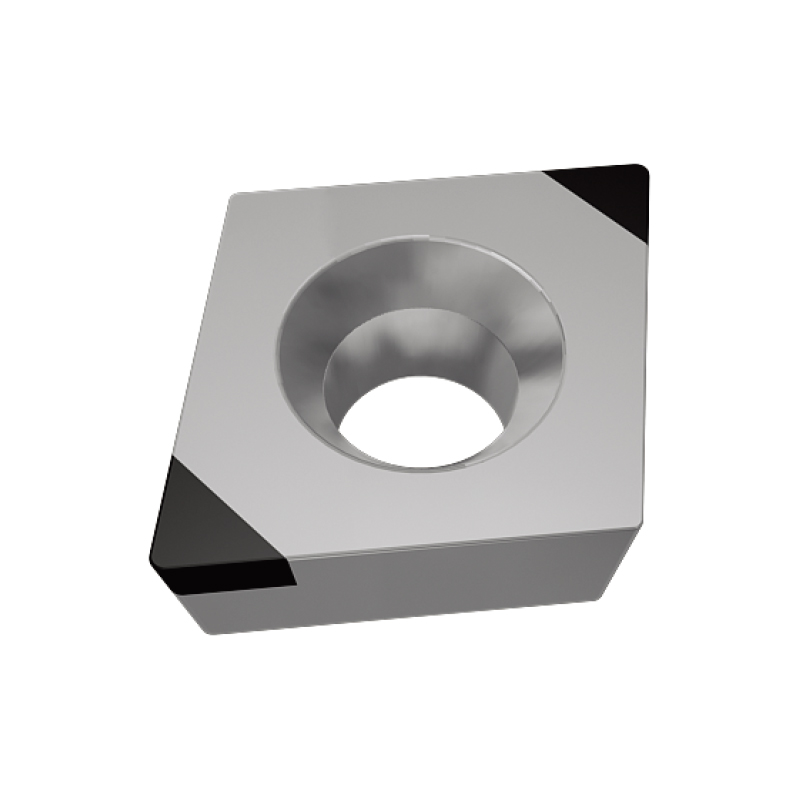

If processing powder metallurgy parts on the CNC lathe above, generally will choose ceramic tools and cubic boron nitride tools, carbide tools are generally not wear-resistant. Ceramic tools and cubic boron nitride tools in the processing of powder metallurgy, generally finishing processes, customers can be based on the actual situation and the economics of the use of tools specific choice, such as a large margin, the use of cubic boron nitride tools large margin processing powder metallurgy parts.

Examples of automotive parts processing of hardened steel materials

Examples of automotive parts processing of hardened steel materials

Powder metallurgy solutions for soft materials

Powder metallurgy solutions for soft materials

CBN tool solutions for machining carburised steel materials

CBN tool solutions for machining carburised steel materials

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining