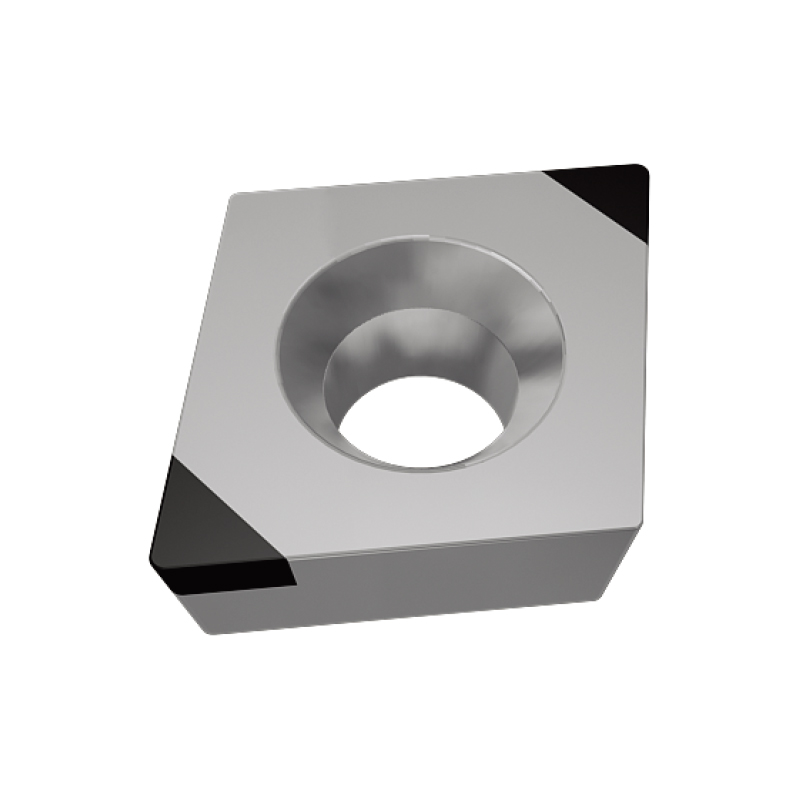

Output shaft gear in 20CrMnTiH material. It is a good performance carburised steel with high hardenability and high low temperature impact toughness, the hardness of the workpiece material is about HRC60, and the machining method is strong intermittent machining.

WSS has selected chipping-resistant materials and increased chamfering of the cutting edges. During the test, a fixed speed of 800r/min, a feed rate of 0.08mm/r, and a machining allowance of 0.2mm were used to control the machining process. While avoiding chipping, the machining accuracy of the workpiece size is stabilised. At the same time, for the edge of the ultra-fine grinding and polishing, and increase the coating to further enhance the performance of the tool. Extend the machining life of the tool.

In addition, due to the long size of the machined part, one clamp and one top clamping is used to enhance the rigidity of the end of the workpiece, and such clamping is conducive to the improvement of machining accuracy and surface quality.

Processing part: Gear face

The optimised machining solution has increased tool life by 40% compared to the original, solving the customer's tool machining problems while achieving the need to reduce costs and increase efficiency.

Examples of automotive parts processing of hardened steel materials

Examples of automotive parts processing of hardened steel materials

Powder metallurgy solutions for soft materials

Powder metallurgy solutions for soft materials

CBN tool solutions for machining carburised steel materials

CBN tool solutions for machining carburised steel materials

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining