A company processing an engine piston, the current customer in the use of A tool manufacturer's tools in the precision turning of the outer circle occurs when the tool life is short, affecting the machining efficiency of the problem, and in the processing of a period of time after the surface of the piston will produce a white mark, which seriously affects the surface quality of the product. In addition, the tool provided by A tool manufacturer is unstable during machining, and only provides one time of regrinding, the above factors make the production cost of auto parts increase steeply.

Workpieces with whitening on the outer round surface

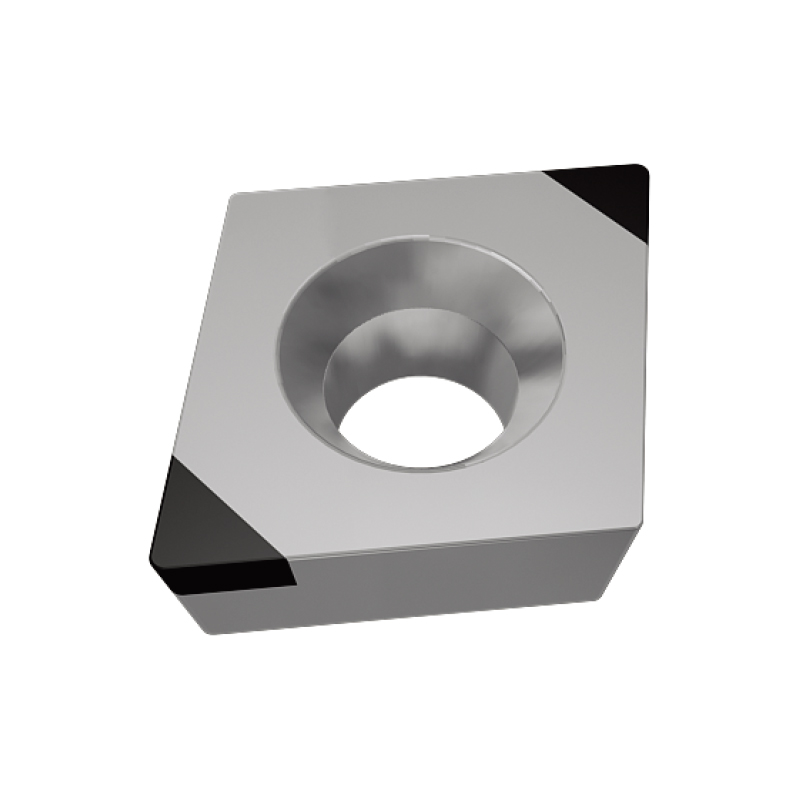

The customer wanted WSS to help them to solve these problems, and WSS technical department selected the most suitable material for the customer according to the machining conditions provided by the customer. At the same time, we carried out research and discussion on tool design for the surface quality of the machined parts, and after analysis, it was thought that the surface of the tool had accumulated chipping tumours after machining for a period of time.

Accumulation tumour in the finishing process will produce a serious impact on the machining results of the phenomenon, so we have increased the front angle of the tool to make the cutting sharper, which can effectively avoid the occurrence of accumulation of tumour phenomenon. In addition, for the customer's request to reduce production costs, we designed the tool can be sharpened many times, better quality to ensure that the tool is cost-effective.

WSS tool machining effect

After a company's test results feedback, WSS tool life than the original tool to improve 35%, and machining out of the surface quality is good, no white marks.WSS for the customer's requirements for the design of the tool, the professional team to provide customers with a good solution.

Examples of automotive parts processing of hardened steel materials

Examples of automotive parts processing of hardened steel materials

Powder metallurgy solutions for soft materials

Powder metallurgy solutions for soft materials

CBN tool solutions for machining carburised steel materials

CBN tool solutions for machining carburised steel materials

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining

WSS Attends 2023 Seminar on Advanced Tooling Technology in High Precision Gear Machining